Most Popular Products

Single Head Auto Powder Filling Machine

Single Head Auto Powder Filling Machine Specification

- Temperature

- Ambient

- Usage & Applications

- Filling of powder products like spices, pharmaceutical powders, food powders, chemicals, etc.

- Noise Level

- <75 dB

- Phase

- Single Phase

- Frequency

- 50 Hz

- Features

- High speed, precise filling, easy operation, low maintenance, stainless steel construction, user-friendly PLC control

- Type

- Single Head Auto Powder Filling Machine

- Material

- Stainless Steel

- Capacity

- 10g to 1000g per fill (adjustable)

- Computerized

- Yes

- Control Mode

- Automatic

- Voltage

- 220V / 50Hz

- Power

- 1.5 kW

- Weight (kg)

- Approx. 200 kg

- Dimension (L*W*H)

- 900 mm x 750 mm x 1800 mm

- Color

- Silver (Metallic Finish)

- Hopper Capacity

- 35 Litres

- Air Compressor Requirement

- 6 kg/cm² (if required for system)

- Display Interface

- Touch Screen HMI

- Filling Accuracy

- ±1%

- Suitable Bottle Diameter

- 30 mm to 90 mm

- Nozzle Type

- Single Filling Nozzle

- Packaging Material Suitability

- PET/Glass/Plastic containers

- Filling Speed

- 15-40 bottles/min (depending on product & pack size)

- Safety Features

- Emergency stop, overload protection, interlocked guards

- Dosage System

- Servo/Stepper Motor Controlled Auger Filler

Single Head Auto Powder Filling Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 2 Week

About Single Head Auto Powder Filling Machine

The offered Single Head Auto Powder Filling Machine is a compact and highly rigid industrial system which is widely used as a packaging unit in various industries to fill plastic containers and pouches of various different sizes at a higher speed and zero wastage. It is commonly used in various industries such as cosmetics, pharmaceuticals, food and many more. It is provided with a large metallic input feeder which is used for the even distribution of the granular material.

Efficient and Accurate Powder Filling

This machine is designed with a servo or stepper motor-controlled auger system, delivering filling accuracy up to 1%. It can adjust dosages between 10 grams to 1000 grams, and its high-speed operation ensures 1540 bottles per minute, maximizing productivity without sacrificing precision. The robust stainless steel body promises longevity and hygienic processing.

User-Friendly PLC & Touch Screen Controls

Operators benefit from the advanced touch screen HMI and user-friendly PLC interface, making setup and adjustments straightforward. With visual monitoring and real-time control, the single head auto powder filling machine minimizes setup time and is ideal for both small and large-scale operations demanding consistency and ease of use.

Comprehensive Safety and Versatility

Safety is paramount, with emergency stop, overload protection, and interlocked guards included as standard features. The machine easily fills PET, glass, or plastic containers within a wide diameter range. Its adaptability allows it to efficiently process a diverse spectrum of granular and powder products in various manufacturing environments.

FAQs of Single Head Auto Powder Filling Machine:

Q: How does the Single Head Auto Powder Filling Machine maintain filling accuracy?

A: This machine uses a servo or stepper motor-controlled auger filler system which ensures precise control over the dose, achieving a filling accuracy of 1%, regardless of product or container size.Q: What types of bottles and containers can this filling machine handle?

A: The machine is suitable for PET, glass, or plastic containers and can accommodate bottle diameters ranging from 30 mm to 90 mm, offering flexibility for different packaging requirements.Q: When is the air compressor required for the system?

A: An air compressor with 6 kg/cm pressure is required only if specified by the system configuration, especially for container placement or powder settling mechanisms.Q: Where is this machine typically used?

A: It is widely utilized in industries such as food processing, pharmaceuticals, spices manufacturing, and chemical production to fill various powder products efficiently and hygienically.Q: What is the process for operating the machine?

A: Operation is straightforward: fill the hopper with your product, select the desired filling weight (10g1000g) on the touch screen HMI, place the containers, and initiate the automatic filling cycle. The user-friendly PLC manages all dosing and safety parameters.Q: How does this machine benefit manufacturers?

A: Manufacturers benefit from reliable, high-speed, and highly accurate powder filling, reduced operator intervention, ease of maintenance, and enhanced workplace safety, all contributing to higher productivity and product consistency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dry Powder and Injectable Line Machine Category

Eye & Ear Drops Filling & Sealing Machines

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1800 x 900 x 1700 mm

Usage & Applications : Eye and Ear Drop Bottle Filling, Capping & Sealing for Pharmaceutical Industry

Noise Level : <70 dB

Type : Other, Automatic Eye & Ear Drops Filling & Sealing Machine

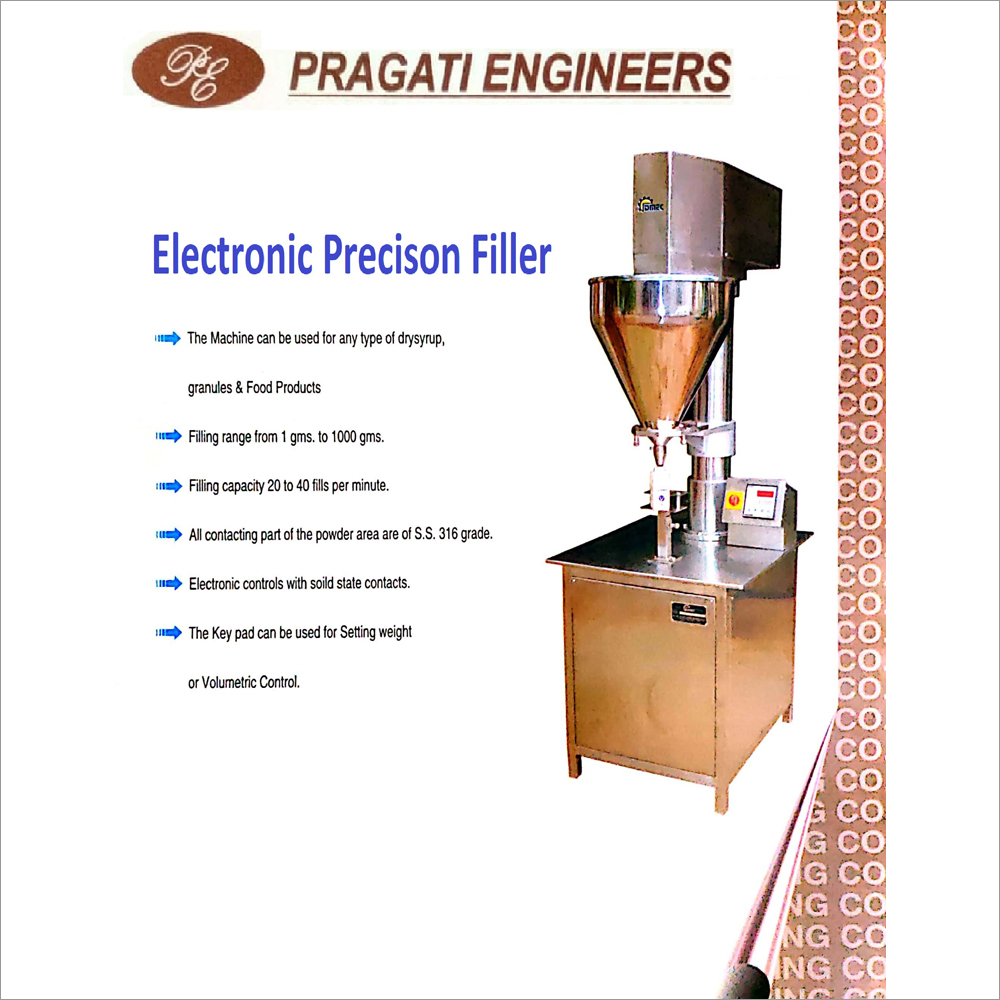

Electronic Precison Filler

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 420 x 330 x 210 mm

Usage & Applications : Liquid Filling, Laboratory and Pharmaceutical Use

Noise Level : Less than 65 dB

Type : Other, Electronic Precision Filler

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese