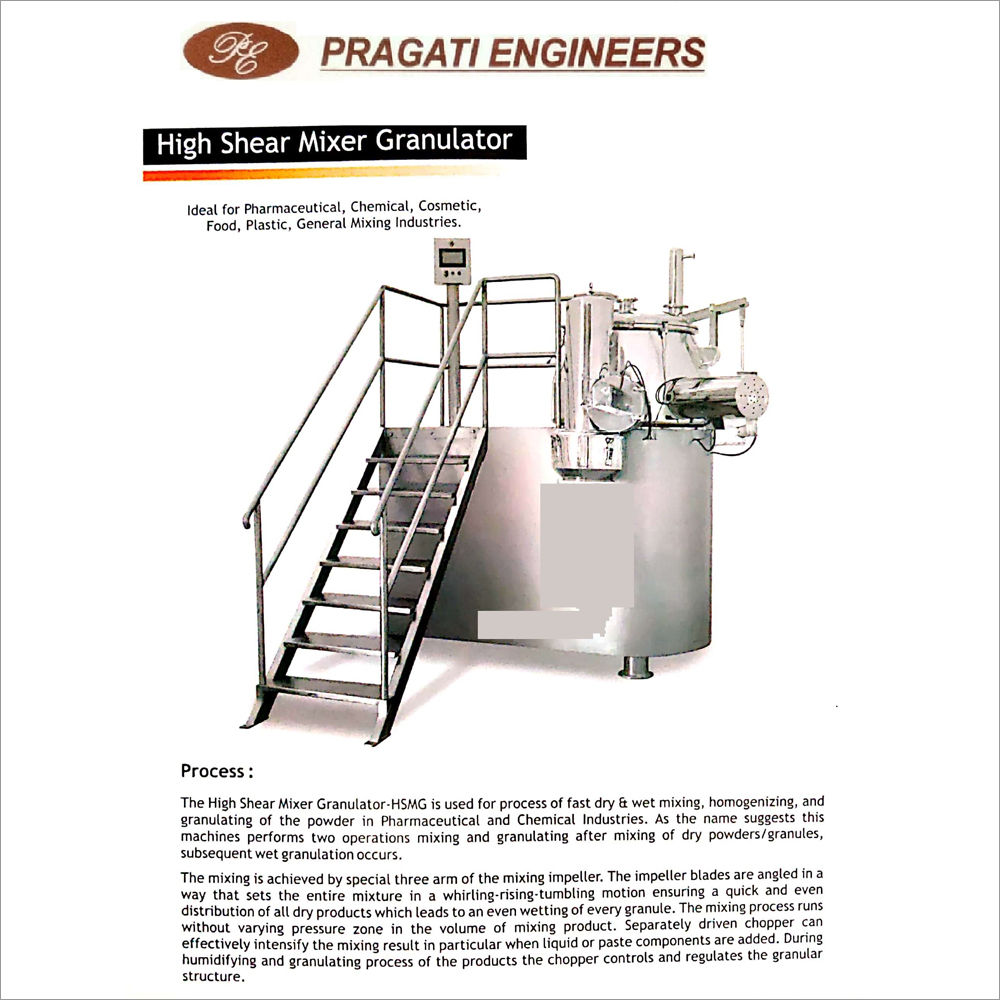

High Shear Mixer Granulator

High Shear Mixer Granulator Specification

- Features

- High speed mixing, efficient granulation, easy cleaning, user-friendly panel

- Phase

- 3 Phase

- Noise Level

- <75 dB

- Usage & Applications

- Granulation and wet mixing in pharmaceutical, chemical, and food industries

- Frequency

- 50 Hz/60 Hz

- Temperature

- Ambient to 80C

- Type

- High Shear Mixer Granulator

- Material

- Stainless Steel (SS 316 or SS 304)

- Capacity

- 50 L to 600 L (customizable)

- Computerized

- Yes (Optional)

- Control Mode

- Automatic / Semi-Automatic

- Voltage

- 220V/380V/415V (as per requirement)

- Power

- 3 kW to 20 kW (model dependent)

- Weight (kg)

- 800 kg to 2500 kg (approx.)

- Dimension (L*W*H)

- Variable as per model (e.g., 2500x1600x2200 mm)

- Color

- Stainless Steel Finish

- Service Support

- On-site and remote technical support

- Batch Time

- 8-12 minutes per batch

- Drive Motor

- Heavy-duty, energy-efficient motor

- Safety Interlocks

- Provided for operational safety

- Cleaning

- CIP system compatible

- Compliance

- cGMP and FDA compliant

- Mounting Type

- Floor-mounted

- Power Supply

- AC supply, customizable as per international standards

- Finish Type

- Mirror/Matt as per request

- Dust Extraction Port

- Available

- Control System

- PLC with HMI (optional)

- Application Range

- Pharmaceutical, Food, Chemical, Cosmetic industries

- Chopper Speed

- 1000-3000 rpm

- Discharge Mode

- Pneumatic or manual

- Mixing Bowl Volume

- Up to 800 Litres (custom models available)

- Impeller Speed

- 50-300 rpm (adjustable)

High Shear Mixer Granulator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 2 Week

About High Shear Mixer Granulator

Advanced Mixing Technology for Superior Granulation

Our High Shear Mixer Granulator incorporates variable-speed impellers and high-speed choppers, ensuring highly uniform mixing and granule formation. The equipment is suitable for a wide range of applications, delivering consistent results in pharmaceutical, chemical, food, and cosmetic manufacturing. Safety interlocks, dust extraction, and CIP compatibility further enhance operational efficiency and hygiene.

Customizable to Fit Your Production Needs

This mixer granulator is available in standard capacities from 50L to 600L, with custom models up to 800L or more upon request. Finishes, power requirements, mounting, discharge options, control systems, and auxiliary features can all be tailored based on your specific process and international compliance requirements. On-site and remote support is also available for seamless integration.

FAQs of High Shear Mixer Granulator:

Q: How does the High Shear Mixer Granulator improve granulation efficiency?

A: By utilizing a combination of adjustable impeller (50300 rpm) and chopper speeds (10003000 rpm), the mixer achieves rapid, uniform granule formation within 812 minutes per batch. Its high shear action ensures optimal particle size distribution and mixing homogeneity, leading to high-quality granules suitable for direct tablet compression or other processing.Q: What industries and applications is this mixer granulator suited for?

A: The High Shear Mixer Granulator is designed for granulation and wet mixing in pharmaceutical, food, chemical, and cosmetic industries. It is ideal for producing granules used in tablet making, instant foods, confections, detergents, and other products where particle size uniformity and efficient mixing are critical.Q: When is it advisable to use pneumatic versus manual discharge?

A: Pneumatic discharge is recommended when frequent, quick, or remote-controlled emptying is needed, especially in large-scale or automated environments. Manual discharge offers greater control for smaller batches or where precise handling is required. Both options can be selected based on batch size and production style.Q: Where can these mixers be installed, and what are the space requirements?

A: This equipment is floor-mounted, requiring a robust level surface and adequate space for operation and maintenance. Dimensions vary by modelfor example, a common unit measures 2500x1600x2200 mm. Exact space requirements depend on chosen capacity and optional features, with custom configurations available to fit your facility.Q: What is the process for cleaning the High Shear Mixer Granulator?

A: The unit is designed for easy cleaning, compatible with Clean-In-Place (CIP) systems. Stainless steel surfaces (SS 316 or 304) and a smooth, mirror or matt finish further facilitate residue removal, reducing downtime and supporting hygienic operation. Regular SOP-based manual or automated CIP cleaning ensures safe and contamination-free production.Q: How user-friendly is the operation and control of this granulator?

A: The mixer offers a user-friendly interface with options for automatic or semi-automatic operation. A PLC system with HMI can be provided for intuitive process control, recipe storage, and monitoring. Safety interlocks and accessible control panels make operation straightforward while maintaining a high level of operational safety.Q: What benefits does this mixer granulator offer over traditional mixing solutions?

A: Compared to traditional mixers, this high shear granulator provides faster processing (812 minutes/batch), superior mixing homogeneity, lower noise (<75 dB), compliance with cGMP/FDA standards, and support for modern cleaning and automation technologies. It minimizes labor intensity, enhances product consistency, and supports scalable operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Granulation Line Machines Category

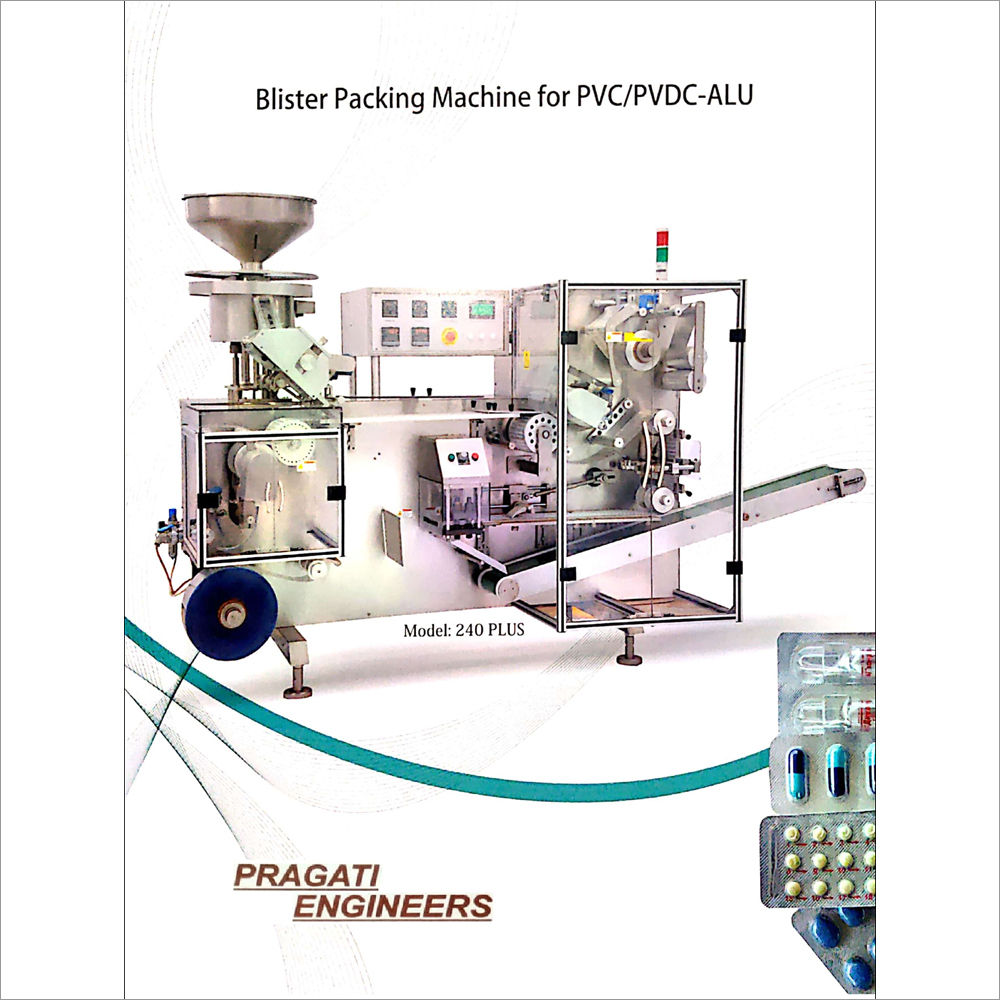

Blister Packing Machine For PVC-PVDC-ALU

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 4.5 kW

Material : Stainless Steel

Features : Automatic feeding, precise cutting, high sealing quality, easy format changeover

Control Mode : Other, PLC Control

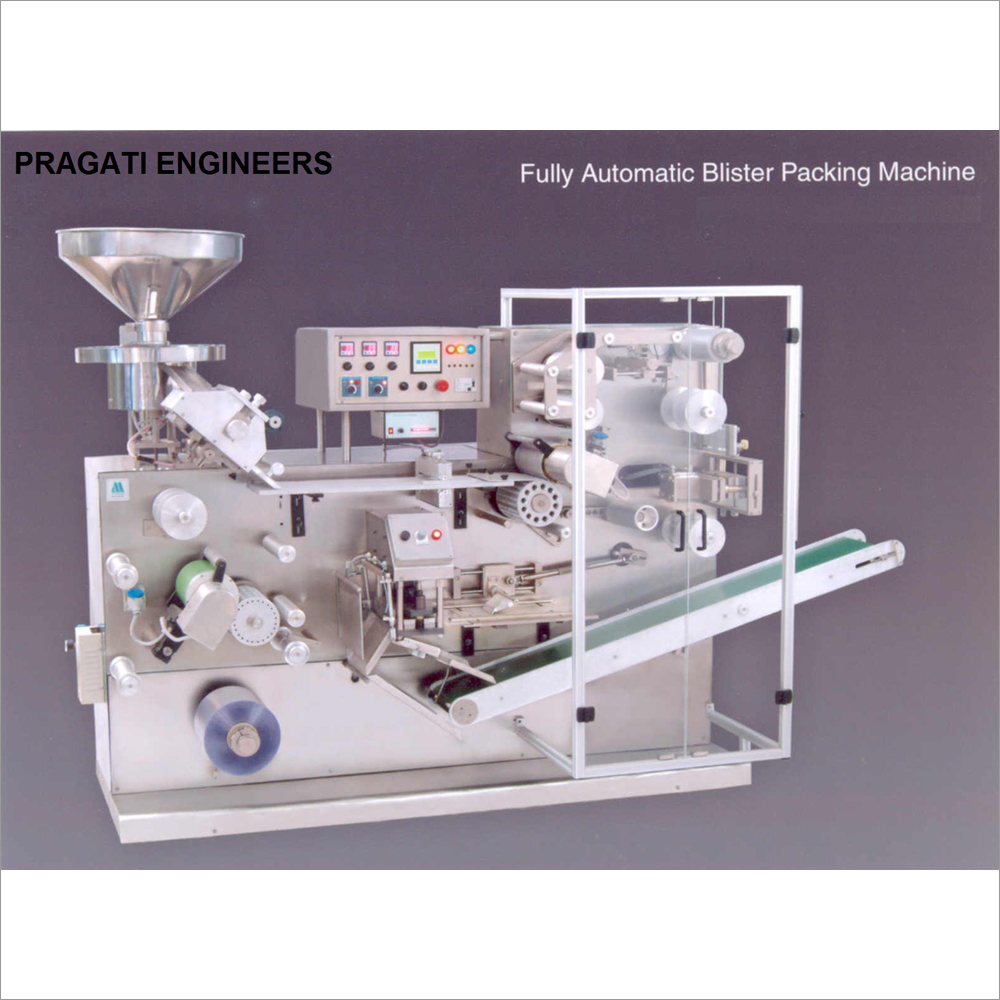

Fully Automatic Blister Packing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 4.5 kW

Material : Stainless Steel

Features : High efficiency, Easy operation, Accurate sealing, Automatic feeding, PLC control, Servodriven

Control Mode : Other, PLC Control with Touchscreen Interface

Strip Packing Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 2.5 kW

Material : Stainless Steel

Features : High speed performance, Easy operation, Low maintenance, Corrosion resistant

Control Mode : Other, PLC Control

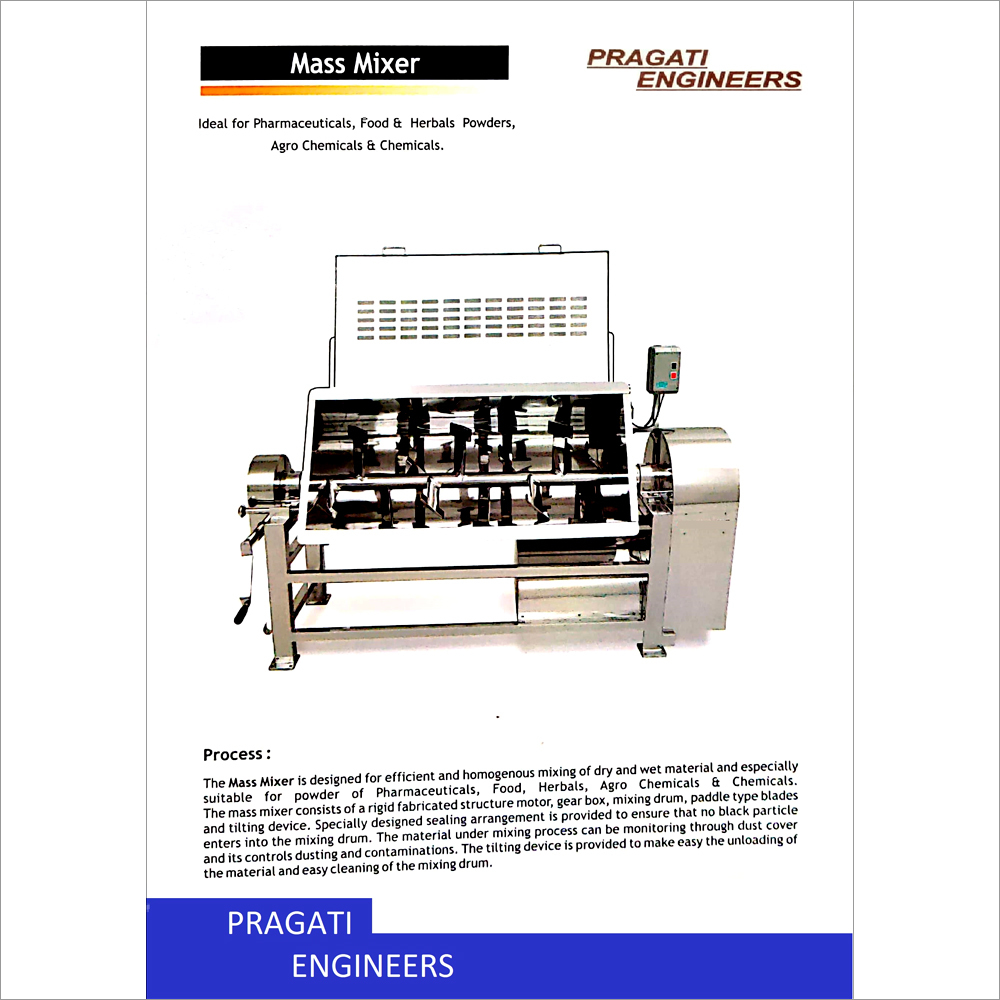

Mass Mixer

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 2 HP to 7.5 HP (Depending on Model)

Material : Stainless Steel (SS 304/316)

Features : Leakproof mixing drum, tilting arrangement for easy discharge, safety guards, easy cleaning, robust construction

Control Mode : SemiAutomatic

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese