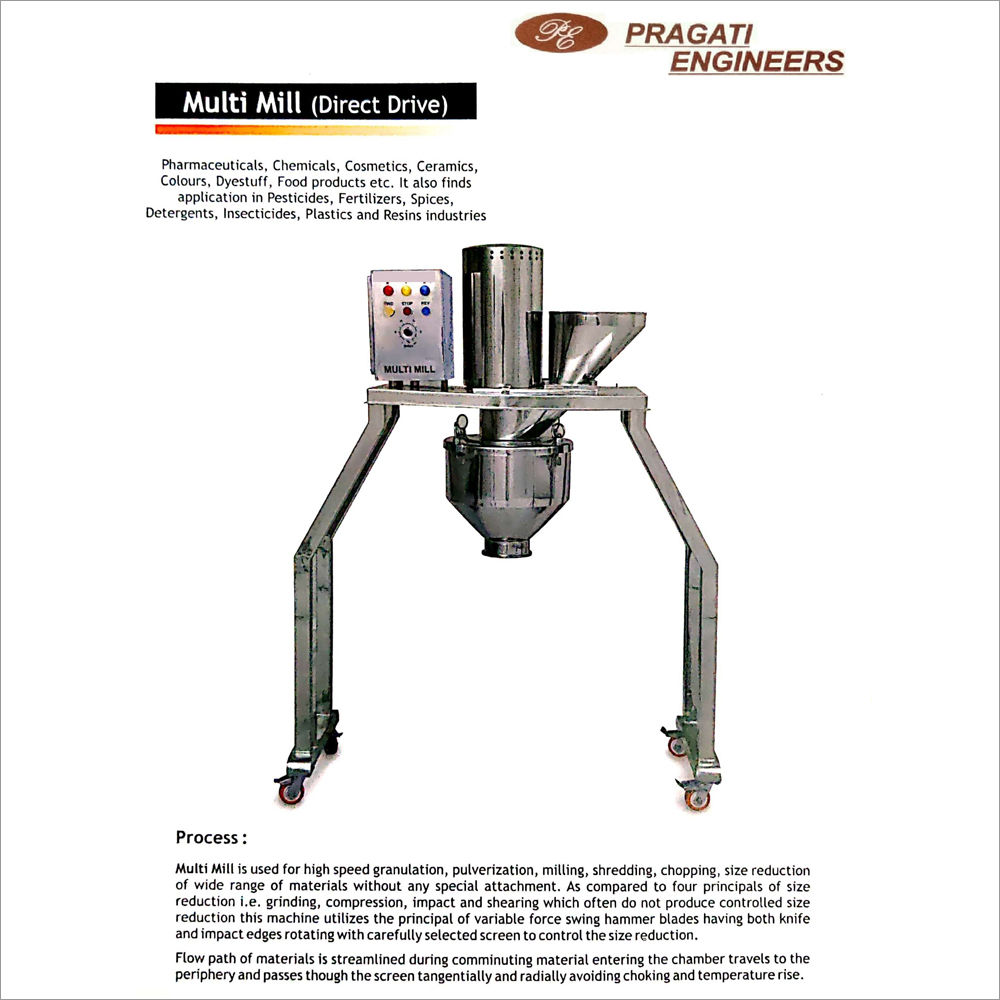

Multi Mill Direct Drive

Multi Mill Direct Drive Specification

- Usage & Applications

- Pharmaceutical, Chemical, Food & Cosmetic Industries for granulation, pulverization, chopping and mixing of materials.

- Phase

- Single Phase / Three Phase

- Frequency

- 50 Hz / 60 Hz

- Noise Level

- Less than 75 dB

- Temperature

- Ambient, Non-heating operation

- Features

- Direct drive technology, interchangeable screens, easy cleaning, GMP compliance, no belt transmission, low maintenance

- Type

- Multi Mill Direct Drive

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 50 kg/hr to 200 kg/hr (Depending on model and product)

- Computerized

- No

- Control Mode

- Manual / Semi-Automatic

- Voltage

- 220 V / 440 V

- Power

- 2 HP to 5 HP

- Weight (kg)

- Approx. 110 kg

- Dimension (L*W*H)

- 650 x 500 x 1200 mm

- Color

- Silver

- Material Feed Size

- Up to 12 mm

- Cleaning

- Completely detachable for easy cleaning

- Mounting Type

- Mobile on castor wheels

- Number of Blades

- 12 (Rotor with knife and scrapper blades)

- Finish Type

- Mirror/Matte as per requirement

- Rotor Speed

- 750 to 3000 RPM (variable speed)

- Discharge Height

- 370 mm

- Compliance

- GMP, cGMP Standards

- Safety Interlocks

- Available for operator protection

- Screen Diameter

- 250 mm

Multi Mill Direct Drive Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 2 Week

About Multi Mill Direct Drive

Advanced Direct Drive Efficiency

This Multi Mill features innovative direct drive technology that eliminates belt transmission, reducing energy loss and mechanical wear. Variable speed control allows users to optimize processing according to product requirements, ensuring efficient granulation, pulverization, chopping, and mixing. The robust stainless steel construction ensures durability and meets stringent industry standards, including GMP and cGMP compliance.

User-Centric Design & Versatility

The design is focused on operator safety and user convenience. Safety interlocks prevent accidents during operation, while the units mobile castor wheels facilitate movement within the workspace. Complete detachment means cleaning and maintenance are swift and hassle-free, supporting frequent product changeovers and maintaining high hygiene standards.

FAQs of Multi Mill Direct Drive:

Q: How is the Multi Mill Direct Drive operated and controlled?

A: The Multi Mill Direct Drive is operated in manual or semi-automatic modes using easily accessible controls. Its variable speed rotor (7503000 RPM) lets users tailor processing to match different materials and desired outcomes.Q: What materials and applications is this mill designed for?

A: This multi mill processes materials such as granules, powders, and lumps in pharmaceutical, chemical, food, and cosmetic industries. It is ideal for granulation, pulverization, chopping, and mixing applications.Q: When should the interchangeable screens be used, and what benefit do they provide?

A: Interchangeable screens are selected based on the size reduction requirement for each processing batch. This flexibility lets users achieve various granule sizes and ensures the machine adapts efficiently to changing product needs.Q: Where can the Multi Mill Direct Drive be installed, and is it easy to relocate?

A: The units compact dimensions and mobile castor wheel mounting allow it to be easily moved and installed across various production areas. It is suitable for environments requiring frequent relocation or reconfiguration.Q: What process and safety safeguards protect operators during use?

A: Safety interlocks are integrated to prevent operation if access panels or guards are not in place, reducing operator risk. The machine also operates at noise levels below 75 dB for a safer and more comfortable working environment.Q: How does the design facilitate cleaning and maintenance?

A: The mill is completely detachable, allowing quick and thorough cleaning between batches. This reduces downtime and helps maintain GMP standards in hygiene-critical industries like pharmaceuticals and food processing.Q: What are the primary benefits of choosing a direct drive multi mill over traditional models?

A: The direct drive mechanism eliminates belt transmission, resulting in lower energy losses, less maintenance, smoother operation, and improved reliability. Combined with variable speed and high-quality stainless steel construction, it delivers consistent performance and long-lasting durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Granulation Line Machines Category

Strip Packing Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Adjustable sealing temperature up to 300C

Dimension (L*W*H) : 2100 x 850 x 1700 mm

Features : High speed performance, Easy operation, Low maintenance, Corrosion resistant

Material : Stainless Steel

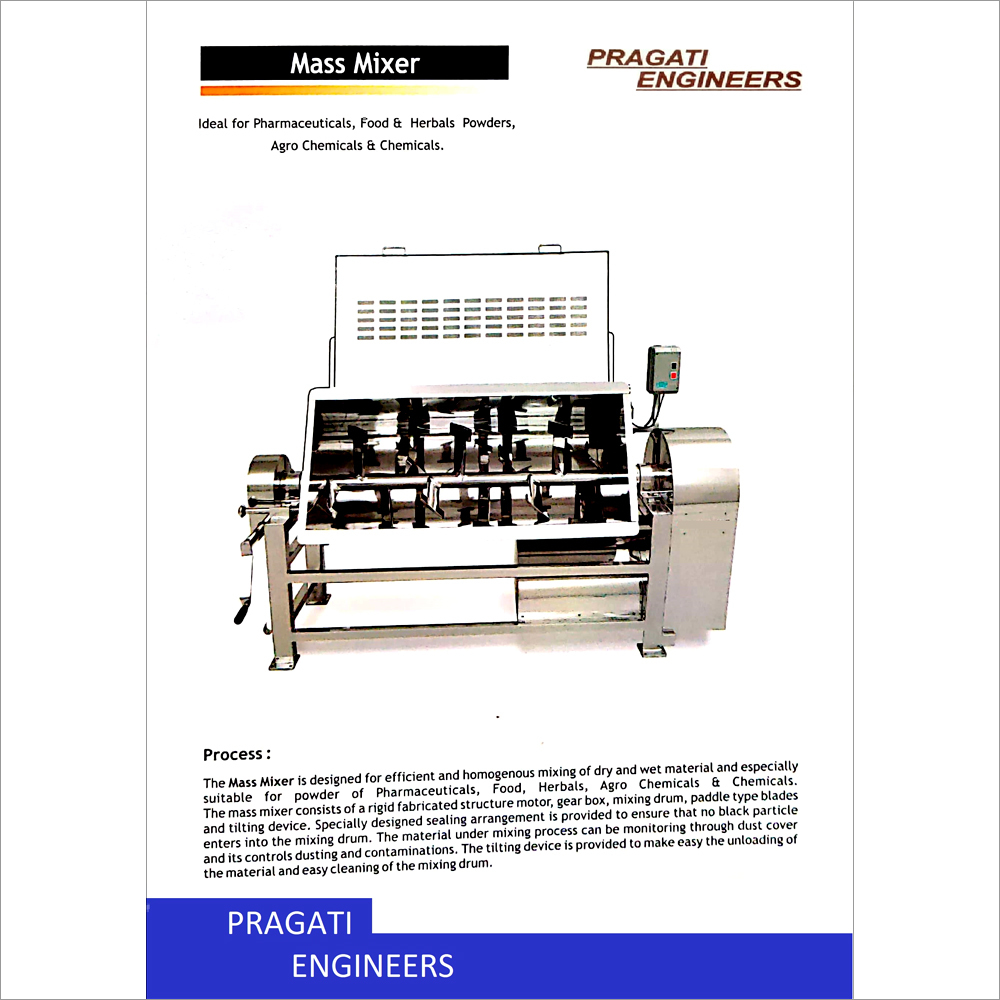

Mass Mixer

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Ambient

Dimension (L*W*H) : Varies with Model, e.g., 2000 x 800 x 1150 mm for 200 kg model

Features : Leakproof mixing drum, tilting arrangement for easy discharge, safety guards, easy cleaning, robust construction

Material : Stainless Steel (SS 304/316)

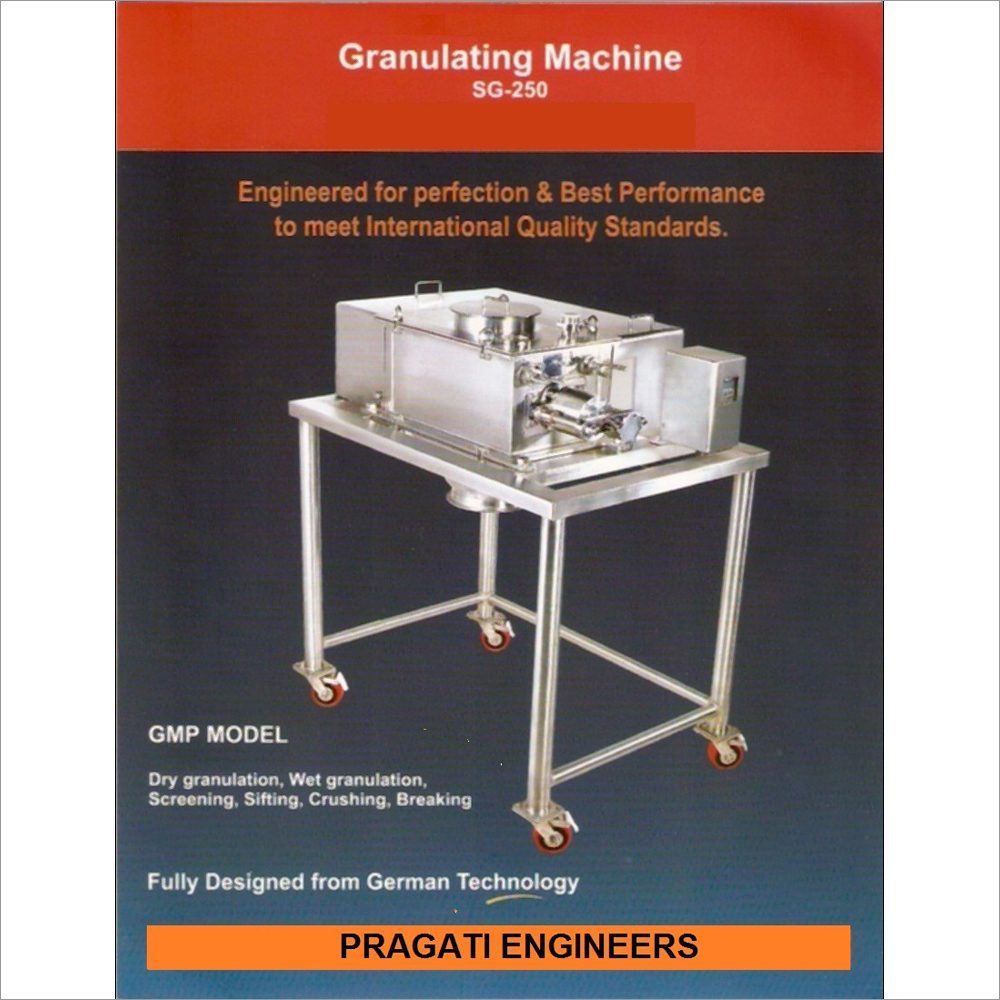

Horizontal Oscillating Granulator

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Ambient

Dimension (L*W*H) : 1200 x 800 x 1200 mm (may vary as per design)

Features : Easy cleaning, Sturdy construction, Interchangeable screens, Low maintenance, High throughput

Material : Stainless Steel (SS 304/316)

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese