Most Popular Products

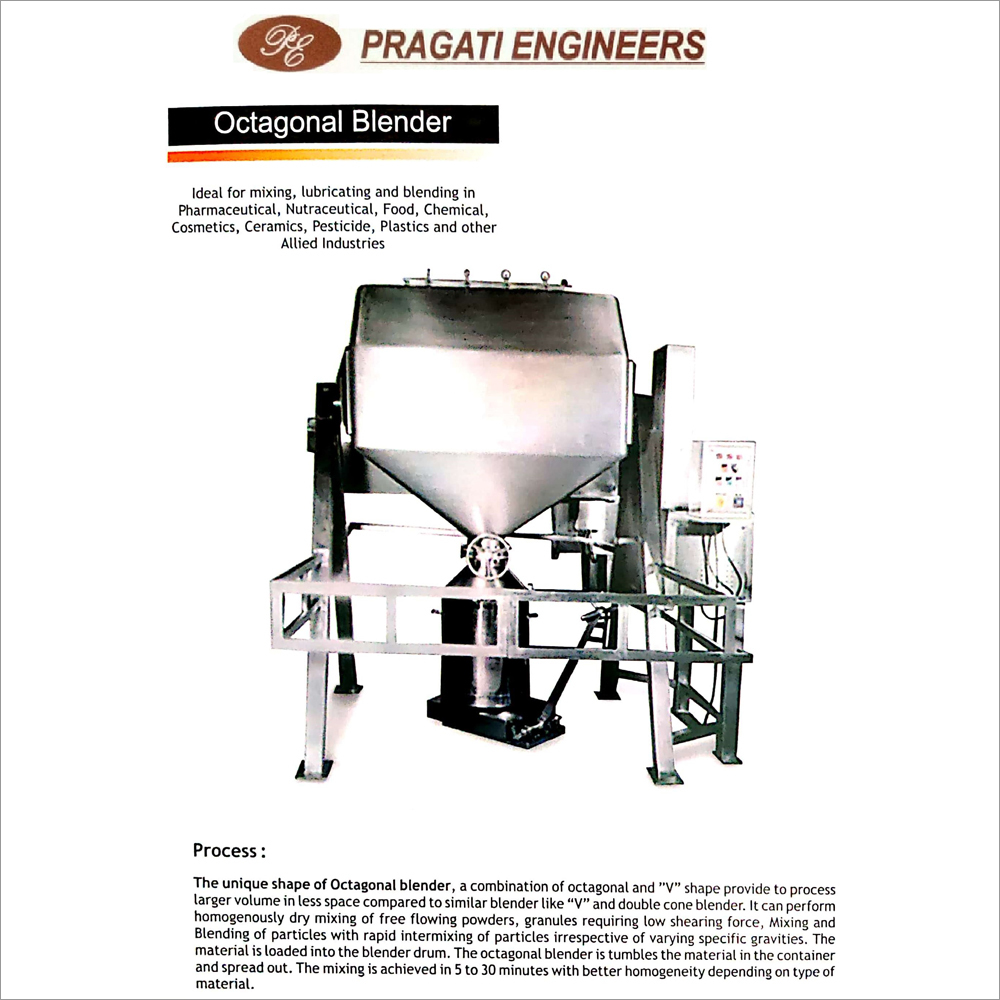

Octagonal Blender

Octagonal Blender Specification

- Features

- Uniform blending, gentle mixing, easy discharge, dust-free operation, low maintenance

- Usage & Applications

- Mixing and blending dry powder and granules in pharmaceutical, food, chemical and cosmetic industries

- Temperature

- Ambient

- Frequency

- 50/60 Hz

- Noise Level

- Low

- Phase

- Three Phase

- Type

- Octagonal Blender

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 50 L to 5000 L

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220-240 V

- Power

- 2 - 10 HP (depending on capacity)

- Weight (kg)

- Approx. 450 - 2000 kg

- Dimension (L*W*H)

- Varies with capacity (e.g. 1250 x 900 x 1700 mm for 250 L model)

- Color

- Silver

- Mounting

- Mounted on robust MS structure with anti-vibration pads

- Drive System

- Direct coupled drive or belt driven

- Blending Efficiency

- Greater than 99%

- Cleaning

- CIP (Clean-In-Place) system optionally available

- Hopper Loading System

- Available with pneumatic or manual loading

- Max Working Time

- Up to 8 hours continuously

- Lining Option

- PTFE lining available for corrosive materials

- Documentation

- GMP documentation provided

- Blending Time

- 5 - 20 minutes/batch (depending on product)

- Safety Features

- Interlock system for operator safety

- Safety Guard

- Full-length safety guard on moving parts

- Gearbox

- Heavy-duty, oil-filled gearbox for smooth operation

- Surface Finish

- Mirror or matt finish as per requirement

- Discharge Valve

- Butterfly type, manually operated

Octagonal Blender Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units, , Per Day

- Delivery Time

- 2 Week

About Octagonal Blender

Octagonal Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. It is a slow speed blender and has removable type baffles mounted on a rectangular shell. The important feature of the machine is easy to wash in place. This is supplied with a bin charging system or can be designed for vacuum charging. Octagonal Blender is very useful for pharmaceutical industries wherein gentle blending of dry granules of powder is to be done.

Superior Blending Performance

Achieve excellent blending efficiency greater than 99%, ensuring homogeneity in every batch. The Octagonal Blenders unique geometry and direct coupled or belt-driven system gently mix powders and granules, preventing degradation and facilitating uniform ingredient distribution in 5 to 20 minutes per batch.

Enhanced Safety & User Convenience

Operator safety is prioritized through a full-length safety guard on moving parts and an interlock system. The blenders ergonomic design features manual or pneumatic loading options, butterfly discharge valve for easy material release, and optional Clean-In-Place (CIP) system for effortless cleaning, streamlining processing and minimizing risk.

Adaptable Design for Diverse Needs

Constructed with robust stainless steel and available PTFE lining for corrosive materials, the Octagonal Blender can be tailored to specific operational requirements. Surface finish options include mirror or matt, while capacities range from 50 to 5000 L. Documentation supports GMP compliance, suitable for manufacturers and exporters in pharmaceutical, food, chemical, or cosmetic sectors.

FAQs of Octagonal Blender:

Q: How does the Octagonal Blender ensure uniform blending of powders and granules?

A: The Octagonal Blender utilizes its unique shape along with a direct coupled or belt-driven heavy-duty gearbox to achieve gentle, thorough mixing. Its blending efficiency exceeds 99%, producing a homogeneous blend within 5 to 20 minutes per batch, depending on the product characteristics.Q: What safety features are incorporated in the Octagonal Blender for operator protection?

A: For enhanced operator safety, the blender is equipped with a full-length safety guard covering all moving parts and an interlock system that prevents operation when the guard is open. The robust MS mounting structure with anti-vibration pads further minimizes risks during use.Q: When is the Clean-In-Place (CIP) system recommended for this blender?

A: The optional CIP system is recommended when frequent product changeovers or stringent cleaning protocols are required, such as in pharmaceutical or food industries. It enables easy and thorough internal cleaning without manual intervention, saving time and ensuring compliance with hygiene standards.Q: Where can the Octagonal Blender be installed and used efficiently?

A: The blender is commonly installed in industrial processing facilities such as pharmaceutical, chemical, food, and cosmetic manufacturing plants. Its compact design and anti-vibration mounting make it suitable for space-constrained environments, enabling dust-free operation and low noise levels.Q: What processes and applications can benefit from the Octagonal Blender?

A: The Octagonal Blender is ideal for mixing dry powders, granules, and crystalline materialsuseful in tablet blending, nutritional supplement production, spice mixing, chemical powder preparation, and cosmetic formulation. It ensures gentle handling without particle degradation.Q: How does the PTFE lining option benefit blending of corrosive materials?

A: The PTFE lining is an effective safeguard when processing corrosive materials, as it protects the stainless steel inner surface from chemical reactions. This feature is beneficial for chemical and pharmaceutical applications demanding resistance to aggressive substances.Q: What are the advantages of having manual and pneumatic hopper loading systems?

A: Manual loading provides simplicity and control for operators handling small batches, while pneumatic loading automates the process for larger volumes, improving speed and hygiene, and reducing dust or spillage during material transfer into the blender.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Granulation Line Machines Category

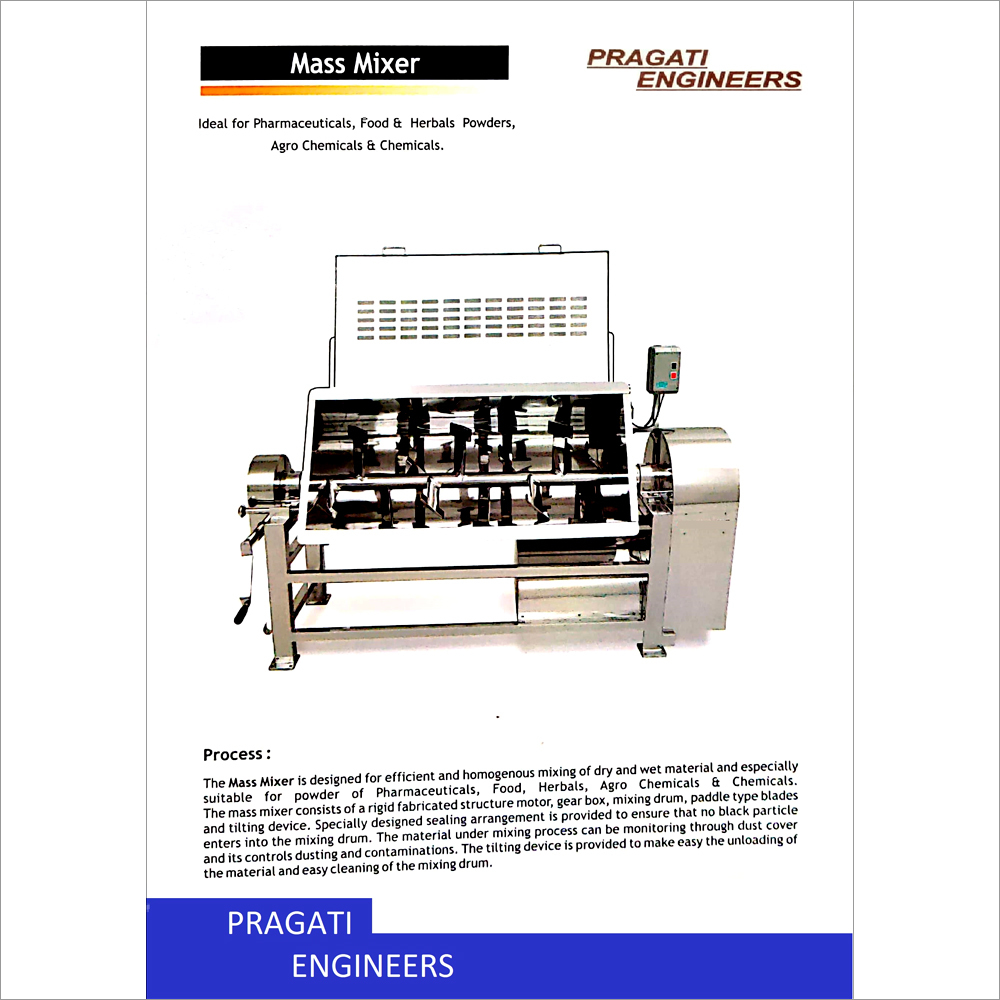

Mass Mixer

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 2 HP to 7.5 HP (Depending on Model)

Temperature : Ambient

Voltage : 220 415 V

Color : Metallic / Silver

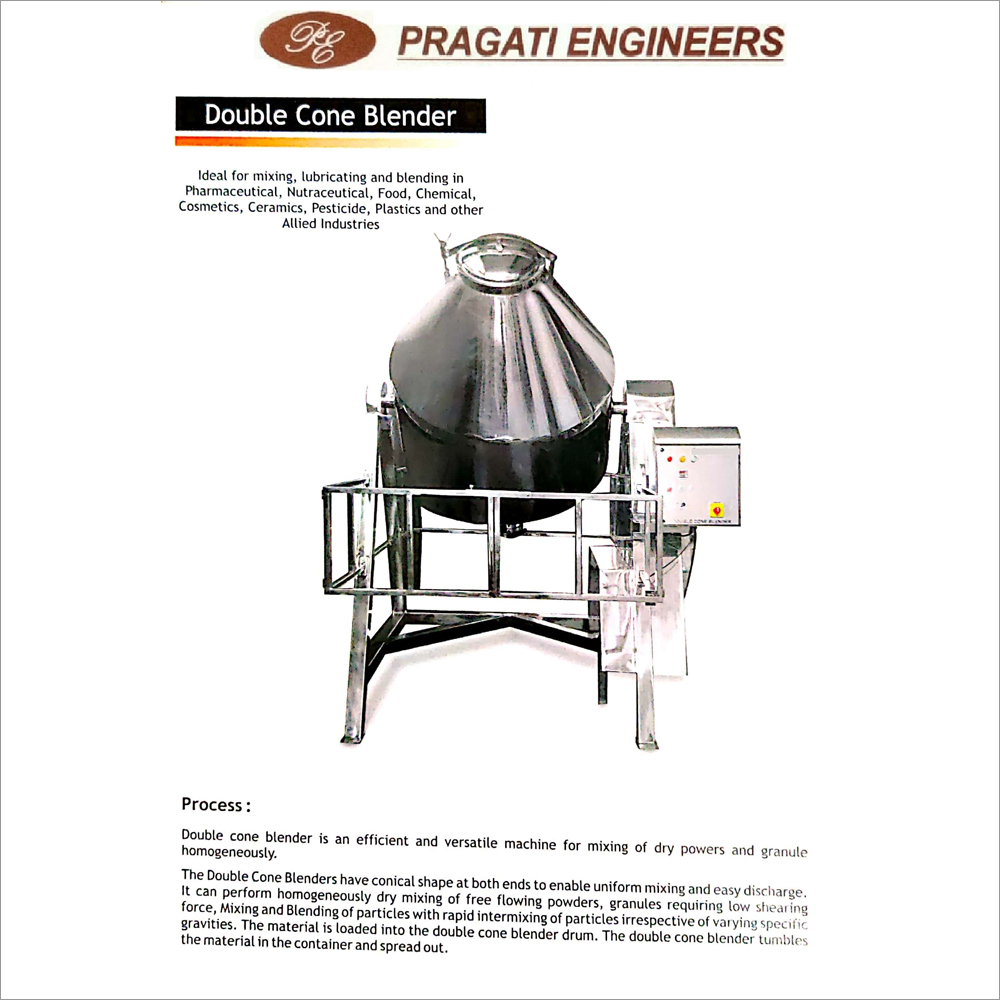

Double Cone Blender

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 0.5 HP to 10 HP (as per model/capacity)

Temperature : Ambient (not intended for heated processing)

Voltage : 220V/380V/415V (as per requirement)

Color : Metallic Silver

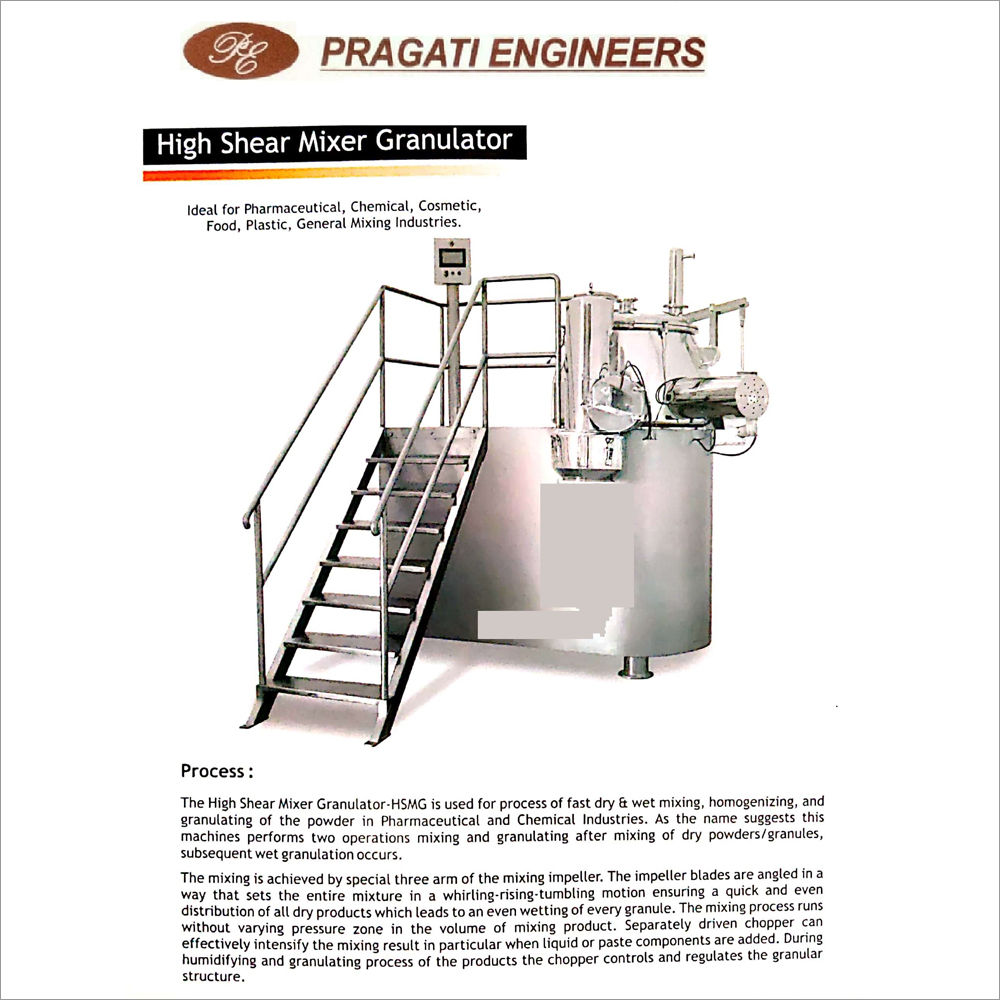

High Shear Mixer Granulator

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 3 kW to 20 kW (model dependent)

Temperature : Ambient to 80C

Voltage : 220V/380V/415V (as per requirement)

Color : Stainless Steel Finish

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese