Leak Tester

Leak Tester Specification

- Product Type

- Leak Tester

- Material

- Mild Steel

- Application

- Industrial leak detection

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Drive Type

- Electric

- Accuracy

- 1% of FS

- Power Source

- Electric

- Voltage

- 220V

- Weight (kg)

- 15 kg

- Dimension (L*W*H)

- 350 250 200 mm

- Capacity

- Up to 5 bar test pressure

- Feature

- Robust construction, easy to operate

- Color

- Blue-Grey

- Portability

- Portable

- Test Method

- Pressure Decay

- Operating Temperature

- 10°C - 50°C

- Compliance

- ISO 9001 Certified

- Minimum Order Quantity

- 1 Unit

- Range

- 0-5 bar

- Sample Type

- Flexible or rigid containers, components

- Packaging Type

- Wooden Box

- Display Type

- Analog Gauge

- Safety Features

- Pressure relief valve

- Test Medium

- Air or Inert Gas

Leak Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 2 Week

About Leak Tester

Efficient Leak Detection for Diverse Containers

This semi-automatic leak tester is expertly crafted for manufacturers and exporters needing reliable leak detection in both flexible and rigid containers. With a pressure range up to 5 bar and an analog gauge, it provides accurate and easy-to-read results, contributing to high safety and product integrity.

Portable Design for Industrial Flexibility

Featuring a compact build and weighing just 15 kg, this tester is easily portable across different workstations. Its mild steel construction ensures durability while the manual controls allow adaptability during various inspection processes, making it ideal for on-site or factory-floor usage.

FAQs of Leak Tester:

Q: How does the pressure decay test method work in this leak tester?

A: The pressure decay method involves pressurizing the sample using air or an inert gas and monitoring for any decrease in pressure indicated on the analog gauge. A drop in pressure suggests a possible leak in the tested container or component.Q: What types of samples can be tested with this device?

A: This leak tester can evaluate both flexible and rigid containers and components, making it suitable for a wide range of industrial applications such as bottles, tanks, and manufactured parts.Q: When is this leak tester typically used in the industrial process?

A: It is commonly deployed during quality control stages or final inspection to ensure containers or parts meet leak-tight standards before dispatch or use.Q: Where can the leak tester be used given its portability?

A: Thanks to its compact dimensions and portable design, the leak tester can be utilized in various locations, from workshops and assembly lines to field sites and inspection stations.Q: What safety features are integrated into the leak tester?

A: The device includes a pressure relief valve ensuring safe operation by automatically venting excess pressure, thus protecting the user and the sample from overheating or rupture.Q: How does using this leak tester benefit industrial operations?

A: Employing this tester reduces the risk of leaks in finished products, enhances quality assurance, and ensures compliance with ISO 9001, ultimately safeguarding production standards and customer satisfaction.Q: What is the process for operating the leak tester?

A: After placing the sample inside the device, the operator manually controls the pressurization using the electric drive. The pressure is monitored on the analog gauge, and potential leaks are detected by observing any pressure decay within the set test range.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lab Equipments Category

Friability Tester

Price 80000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Accuracy : 1 Revolution

Weight (kg) : Approx. 68 kg

Control System : Other, Digital

Tablet Dissolution Tester

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Accuracy : 2 rpm or better

Weight (kg) : Approx. 35 kg

Control System : Other, Digital Microprocessor Based

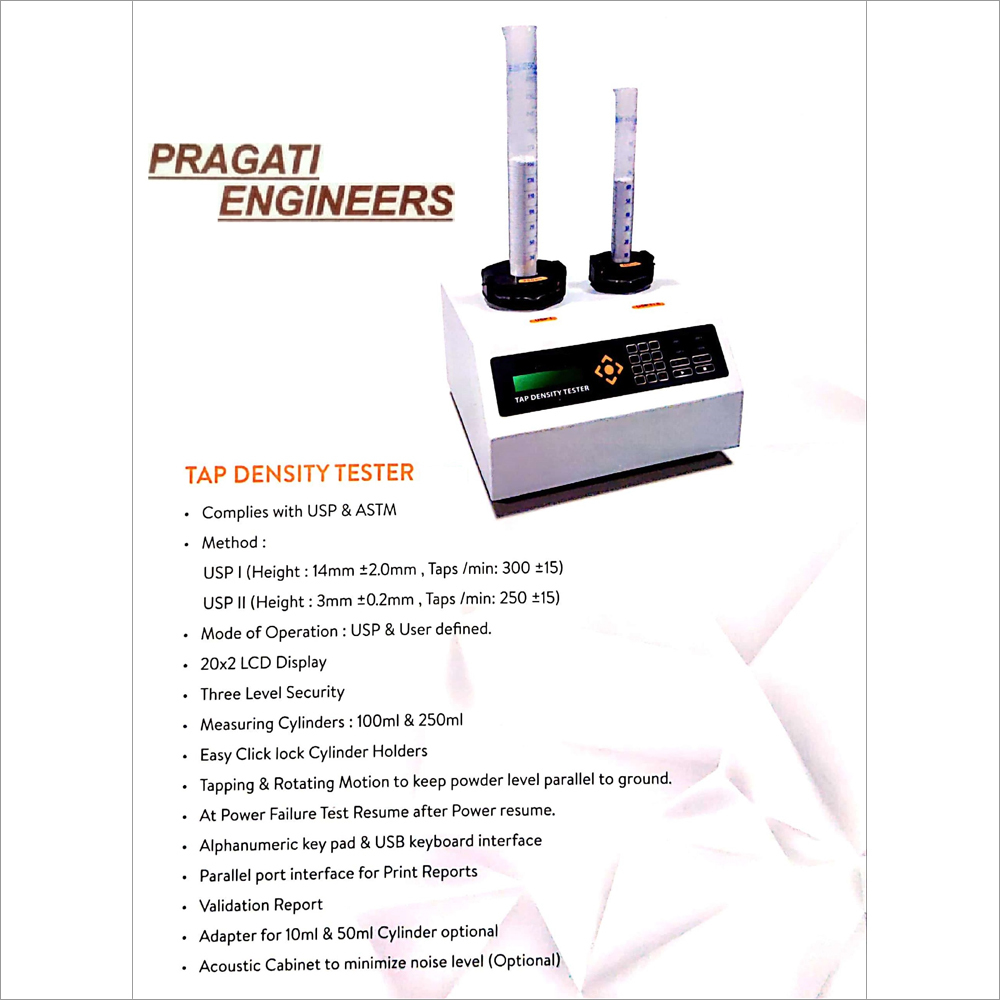

Tap Density Tester

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Accuracy : 1 Count

Weight (kg) : 12 kg (approx)

Control System : Other, Digital Timer with Preset Programmable Counts

Disintegration Tester Synchronous & Non-Synchronous

Price 80000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Accuracy : 1% Display

Weight (kg) : Approx. 15 kg

Control System : Other, Digital Control

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese