Container Filling Machine

Container Filling Machine Specification

- Cooling System

- Air Cooled

- Features

- No container-no fill system, auto rejection, anti-drip filling nozzles

- Accuracy

- 1%

- Frame Type

- Robust Stainless Steel Frame

- Lubricating System

- Centralized automatic lubrication

- Machine Type

- Automatic

- Motor Power

- 1.5 HP

- Voltage

- 220 V

- Model No

- CFM-1500A

- Noise Level

- < 70 dB

- Control System

- Touch Screen HMI

- Production Capacity

- 1500 Containers/hour

- Connectivity Options

- Ethernet, USB

- Power Rating

- 2.2 kW

- Operating Temperature

- 5C to 45C

- Drive

- Servo Motor Driven

- Frequency

- 50 Hz

- Product Type

- Automatic Container Filling Machine

- Technology

- PLC Based Automation

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 2.2 kW

- Pressure

- Adjustable, up to 6 bar

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1200 x 800 x 1800 mm

- Weight (kg)

- 320 kg

- Color

- Stainless Steel

- Usage & Applications

- Liquid filling in chemical, pharmaceutical, food and beverage industries

- Bottle/Container Diameter Supported

- 25 mm to 120 mm

- Operator Interface

- Multi-language Support

- Material of Construction

- SS 304/316

- Discharge Height

- 850 mm

- Safety Features

- Emergency stop, overload protection

- Changeover Time

- Less than 10 minutes

- Integration

- Compatible with upstream and downstream conveyors

- Data Logging

- Batch and User Activity Tracking available

- Cleaning

- CIP (Clean In Place) system

- Fill Volume Range

- 50 ml to 5000 ml

Container Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units, , Per Day

- Delivery Time

- 2 Week

About Container Filling Machine

Efficient and Versatile Filling Capability

Designed for containers with diameters from 25 mm to 120 mm and fill volumes between 50 ml and 5000 ml, the CFM-1500A delivers flexible liquid filling for various industries including pharmaceuticals, chemicals, and beverages. Its auto rejection and anti-drip nozzles maintain product integrity and accuracy, supporting production needs up to 1500 containers per hour.

Advanced Automation and Safety Features

The machine incorporates a PLC-based control system with touch screen HMI that supports multiple languages and real-time data logging. Key safety elements include emergency stop, overload protection, and a no container-no fill system, all housed within a robust, powder-coated stainless steel frame to ensure safe and consistent operation.

Rapid Changeover and Hassle-Free Maintenance

Changeover between container sizes or products is fast, taking less than 10 minutes. The integrated Clean In Place (CIP) system and centralized automatic lubrication minimize downtime and simplify maintenance. This ensures higher output and consistent product quality with reduced manual intervention.

Seamless Integration and Connectivity

Compatible with upstream and downstream conveyors, the CFM-1500A can be easily incorporated into existing production lines. Its connectivity options include Ethernet and USB, enabling effective communication with other devices and facilitating batch management, traceability, and remote diagnostics.

FAQs of Container Filling Machine:

Q: How does the Container Filling Machine ensure accurate filling for different container sizes and volumes?

A: The machine supports containers with diameters from 25 mm to 120 mm and fill volumes of 50 ml to 5000 ml. Its PLC automation system and servo motor drive control filling parameters precisely, guaranteeing 1% accuracy regardless of container size or product viscosity.Q: What are the safety features included in the machine for operator protection?

A: Key safety measures include an emergency stop button, overload protection, and no container-no fill technology. These features prevent accidental operation and protect against equipment damage, ensuring safe usage in busy industrial settings.Q: When is the best time to perform changeover and cleaning on this filling machine?

A: Changeover between different containers or products can be done in less than 10 minutes, and the built-in CIP (Clean In Place) system enables routine cleaning after shifts or product changes. This minimizes downtime and supports optimal hygienic practices.Q: Where can the CFM-1500A be integrated within a production line?

A: The machine is designed for seamless compatibility with upstream and downstream conveyors, making it suitable for integration into automated bottling, packaging, or liquid filling lines in chemical, pharmaceutical, or food and beverage plants.Q: What is the process for operating the Container Filling Machine?

A: Operations are managed via a multi-language touch screen HMI, allowing users to set container sizes, fill volumes, pressure, and speed. The system tracks batches and user activity, and automated features like no container-no fill and auto rejection facilitate streamlined workflows.Q: How does the machine benefit manufacturers in terms of productivity and efficiency?

A: With a production capacity of 1500 containers per hour, fast changeover capability, automated lubrication, and integrated safety functions, the machine increases throughput and reduces human error. Connectivity features enable efficient data management and batch traceability for improved operational control.Q: What materials and durability features are incorporated into the construction of this filling machine?

A: Constructed from SS 304/316 stainless steel with powder coating, the machine is built for durability and corrosion resistance. Its robust frame and air-cooled system further enhance longevity, making it ideal for heavy-duty industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ointment Section Machines Category

Planetary Mixer Jacketed

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Operating Type : Other, SemiAutomatic / Automatic

Surface Treatment : Other, Stainless Steel Polished

Power Source : Other, Electric

Usage & Applications : Food, Pharmaceutical, Cosmetic & Chemical mixing

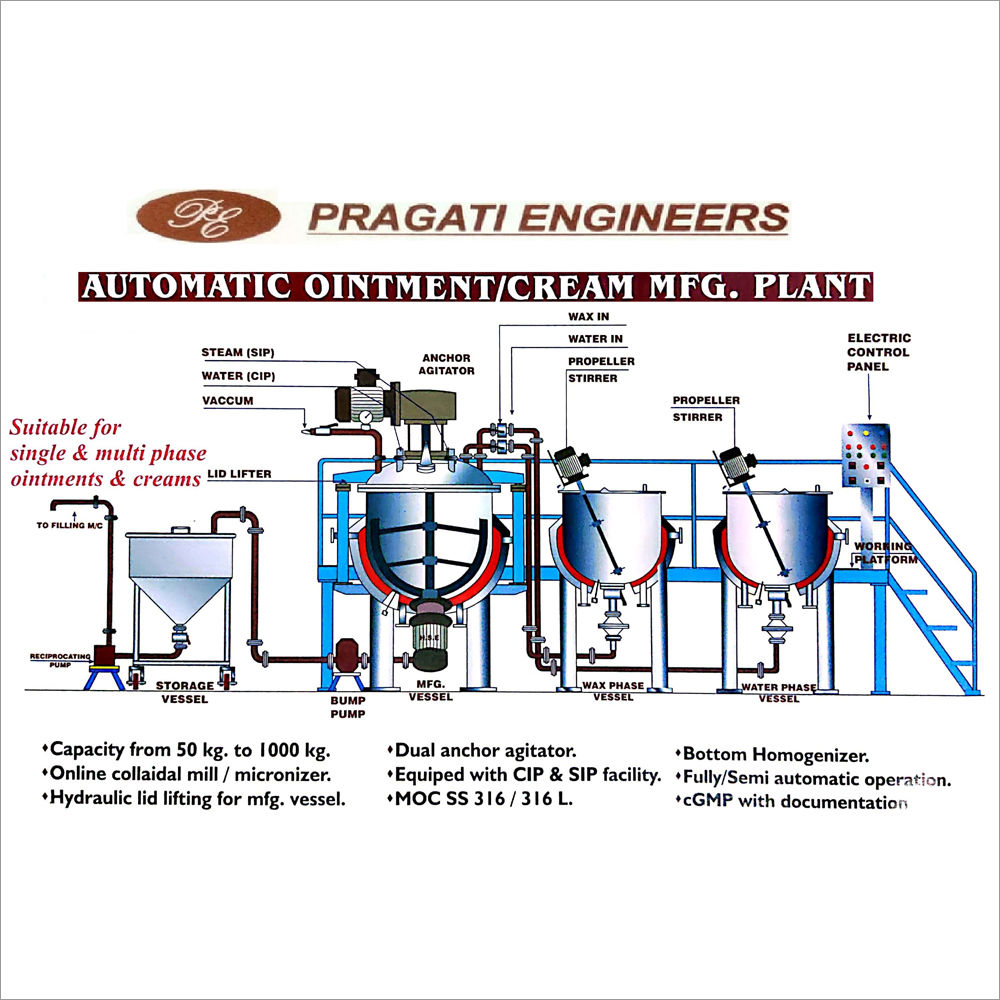

Automatic Ointment Cream Manufacturing Plant

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Operating Type : Automatic

Surface Treatment : Other, Stainless steel 304/316 mirror polish

Power Source : Other, Electric

Usage & Applications : Manufacturing ointments, creams, cosmetics, gels, and pharmaceutical formulations

Automatic Tube Filling & Sealing Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Operating Type : Automatic

Surface Treatment : Coated

Power Source : Electricity

Usage & Applications : Industrial

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese