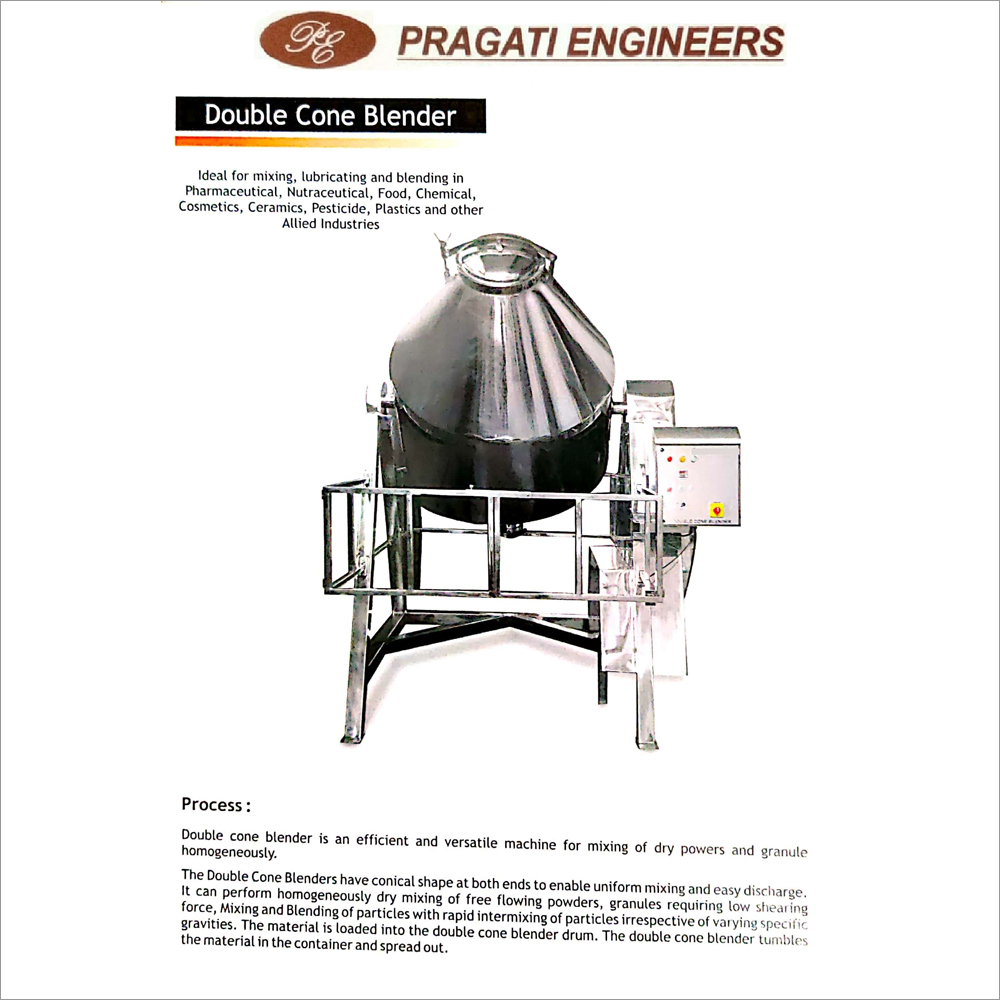

Double Cone Blender

Double Cone Blender Specification

- Noise Level

- 70 dB

- Features

- Uniform mixing, easy discharge, low maintenance, cGMP construction, dust-free operation

- Frequency

- 50 Hz / 60 Hz

- Usage & Applications

- Dry powder/granule mixing in food, chemical, pharmaceutical and cosmetic industries

- Phase

- Three Phase (Single Phase available on request)

- Temperature

- Ambient (not intended for heated processing)

- Type

- Double Cone Blender

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 25 to 5000 Liters (customizable)

- Computerized

- No

- Control Mode

- Manual/Semi-automatic, optional PLC based

- Voltage

- 220V/380V/415V (as per requirement)

- Power

- 0.5 HP to 10 HP (as per model/capacity)

- Weight (kg)

- 300 to 2500 kg (approx., varies by capacity)

- Dimension (L*W*H)

- Varies as per capacity/model

- Color

- Metallic Silver

- Charging & Discharging

- Butterfly or Slide Valve for material charging/discharging

- Filling Percentage

- Recommended up to 60% of total capacity

- Compliance

- Meets GMP standards and CE certified (on request)

- Drive

- Enclosed geared motor with chain and sprocket arrangement

- Safety

- Interlock safety device provided for operator protection

- Documentation

- Calibration and validation documents available

- Blender Barrel Finish

- Mirror or Matte polished finish (internal/external)

- Vacuum Loading

- Vacuum loading provision available as optional feature

- Cleaning

- Designed for easy cleaning, CIP option available

- Mobility

- Casters or fixed supports as per installation requirement

Double Cone Blender Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 2 Week

About Double Cone Blender

Optimal Mixing Efficiency

The Double Cone Blender provides uniform and thorough mixing of dry powders and granules, ensuring product homogeneity for high-quality processing. Its unique double-cone shape coupled with precise filling volume recommendations maximizes blending efficiency while minimizing material wastage. The robust geared motor and chain-sprocket arrangement grant reliable performance batch after batch.

Adaptable to Process Requirements

Choose between butterfly or slide valves for controlled material charging and discharge. The blender accommodates a range of capacities and is available in manual, semi-automatic, or PLC-based controls. Optional features such as vacuum loading and Clean-in-Place (CIP) systems enhance adaptability, catering to diverse process needs in compliance-driven industries.

Operator Safety, Easy Maintenance

Safety is paramount with integrated interlock devices, helping protect operators during operation. The polished interior surface and optional CIP design simplify cleaning, facilitating quick product changeovers and supporting stringent quality demands. Casters and fixed supports offer installation flexibility, and comprehensive documentation ensures seamless validation and calibration.

FAQs of Double Cone Blender:

Q: How does the Double Cone Blender ensure uniform mixing of materials?

A: The unique double-cone design, operating at recommended fill levels of up to 60% of the blenders capacity, creates a tumbling action that thoroughly mixes powders or granules. This geometry promotes consistent blending, with the geared motor drive providing stable operation throughout each batch.Q: What are the available options for charging and discharging materials?

A: The blender offers butterfly or slide valves for charging and discharging your product. These options allow you to select the best fit for your process, ensuring controlled operation, minimal material loss, and dust-free handling.Q: When should the Clean-in-Place (CIP) system be used, and what are its benefits?

A: The CIP system is advisable when fast, thorough cleaning between product batches is needed, especially to meet stringent hygiene or GMP compliance requirements. CIP reduces manual cleaning effort, saves downtime, and ensures high cleanliness standards.Q: Where can the Double Cone Blender be installed, and how is mobility managed?

A: You can install the blender in any production facility, with customization available for pharmaceutical, food, chemical, or cosmetic industries. Depending on your setup, choose between caster wheels for mobility or fixed supports for stationary installation.Q: How is operator safety maintained during the blending process?

A: Operator safety is safeguarded by interlock safety devices, which prevent the blender from operating unless securely closed. This feature protects users during operation and maintenance, aligning with international safety and GMP standards.Q: What is the typical process for using the Double Cone Blender?

A: Materials are loaded through the charging valve, the recommended filling percentage is observed, and the drive is activated for blending. After the set process time, the blended material is discharged through the butterfly or slide valve, ensuring uniform output with minimal residue.Q: What documentation and compliance standards does this blender meet?

A: The Double Cone Blender is supplied with calibration and validation documents. It is GMP compliant and CE certification can be provided on request, facilitating quality assurance, regulatory compliance, and audit readiness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Granulation Line Machines Category

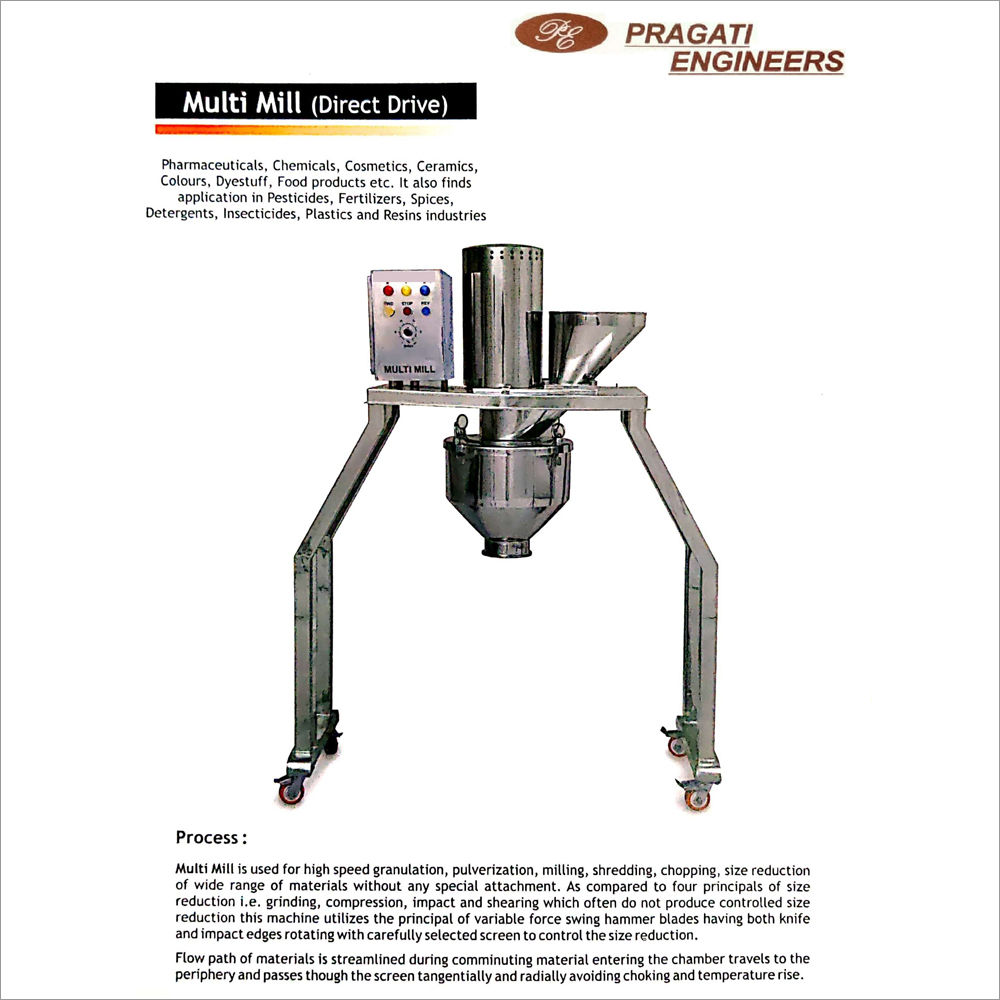

Multi Mill Direct Drive

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Direct drive technology, interchangeable screens, easy cleaning, GMP compliance, no belt transmission, low maintenance

Type : Other, Multi Mill Direct Drive

Material : Stainless Steel (SS 304/316)

Usage & Applications : Pharmaceutical, Chemical, Food & Cosmetic Industries for granulation, pulverization, chopping and mixing of materials.

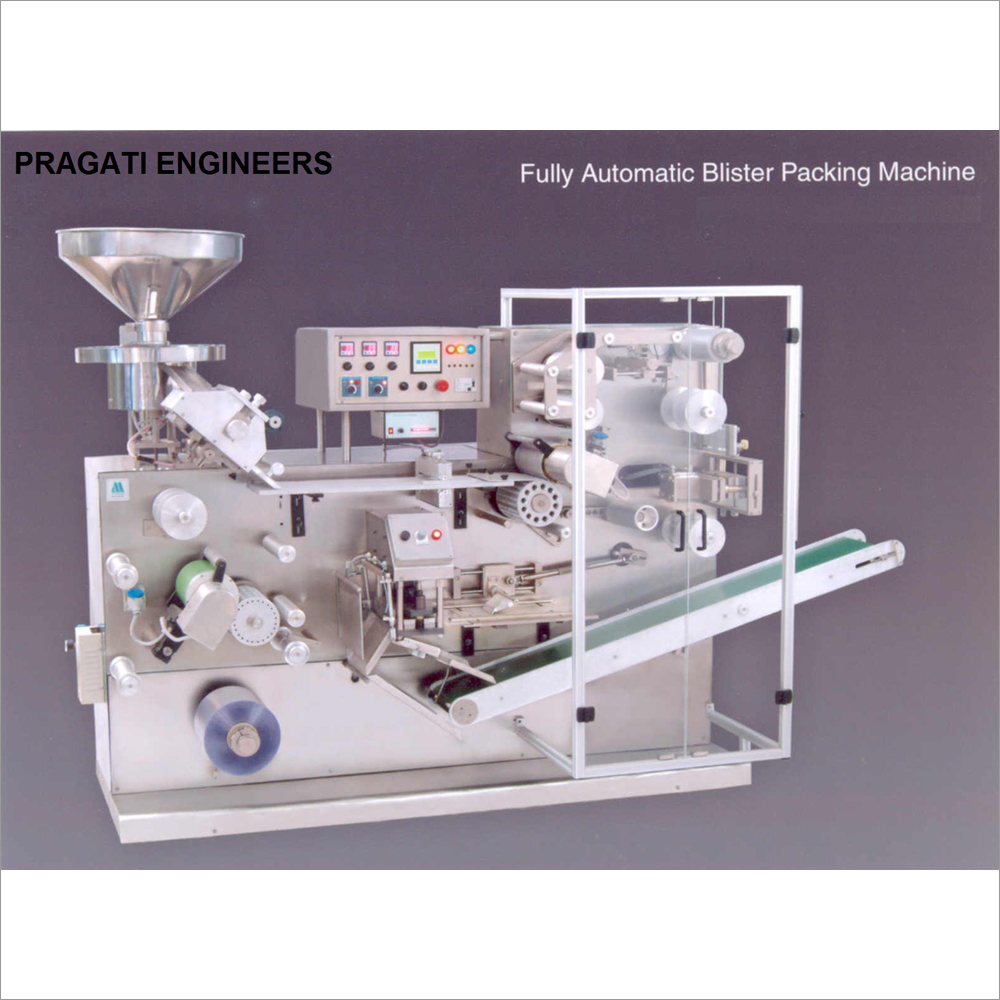

Fully Automatic Blister Packing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : High efficiency, Easy operation, Accurate sealing, Automatic feeding, PLC control, Servodriven

Type : Other, Fully Automatic Blister Packing Machine

Material : Stainless Steel

Usage & Applications : Pharmaceutical tablets, capsules, ampoules, and other products packing

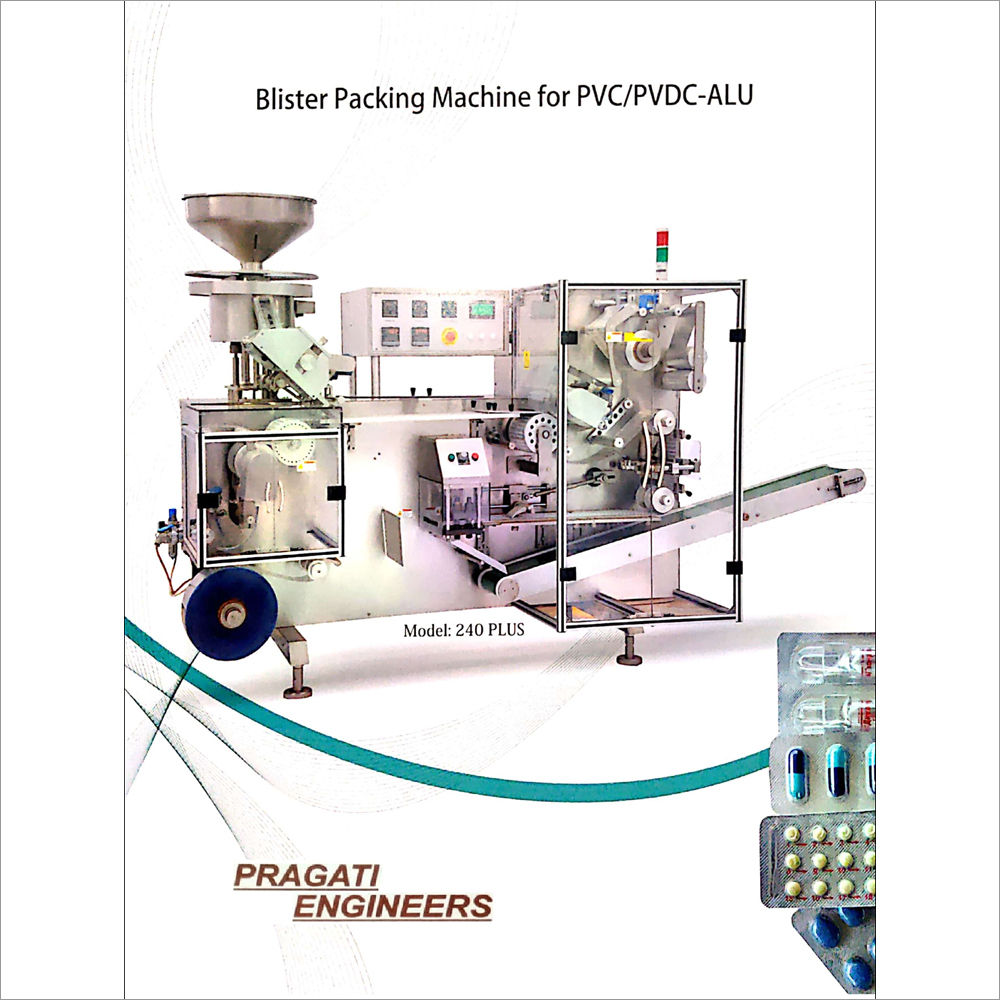

Blister Packing Machine For PVC-PVDC-ALU

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Automatic feeding, precise cutting, high sealing quality, easy format changeover

Type : Other, Blister Packing Machine

Material : Stainless Steel

Usage & Applications : Packing tablets/capsules in pharmaceutical, food, and healthcare industries

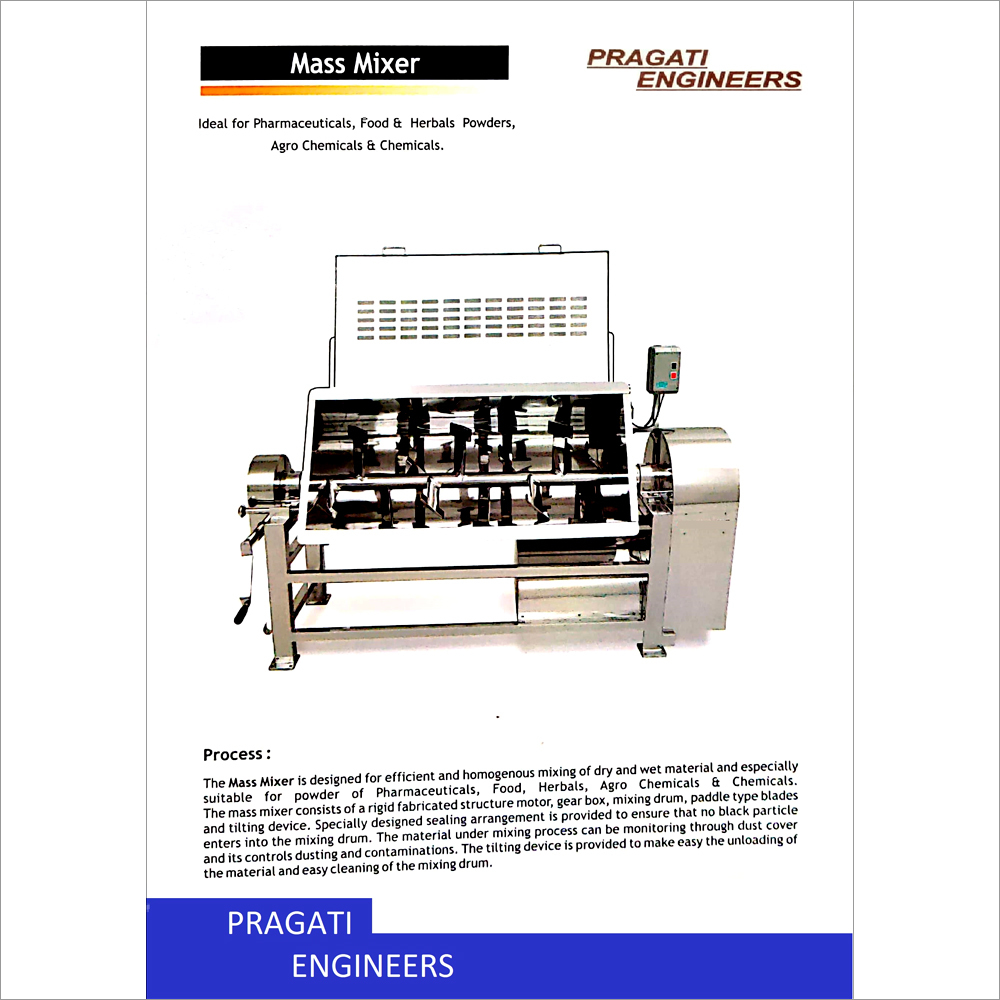

Mass Mixer

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Leakproof mixing drum, tilting arrangement for easy discharge, safety guards, easy cleaning, robust construction

Type : Other, Mass Mixer

Material : Stainless Steel (SS 304/316)

Usage & Applications : Mixing of wet and dry materials, mainly for pharmaceutical, ayurvedic, chemical, and food industries.

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese