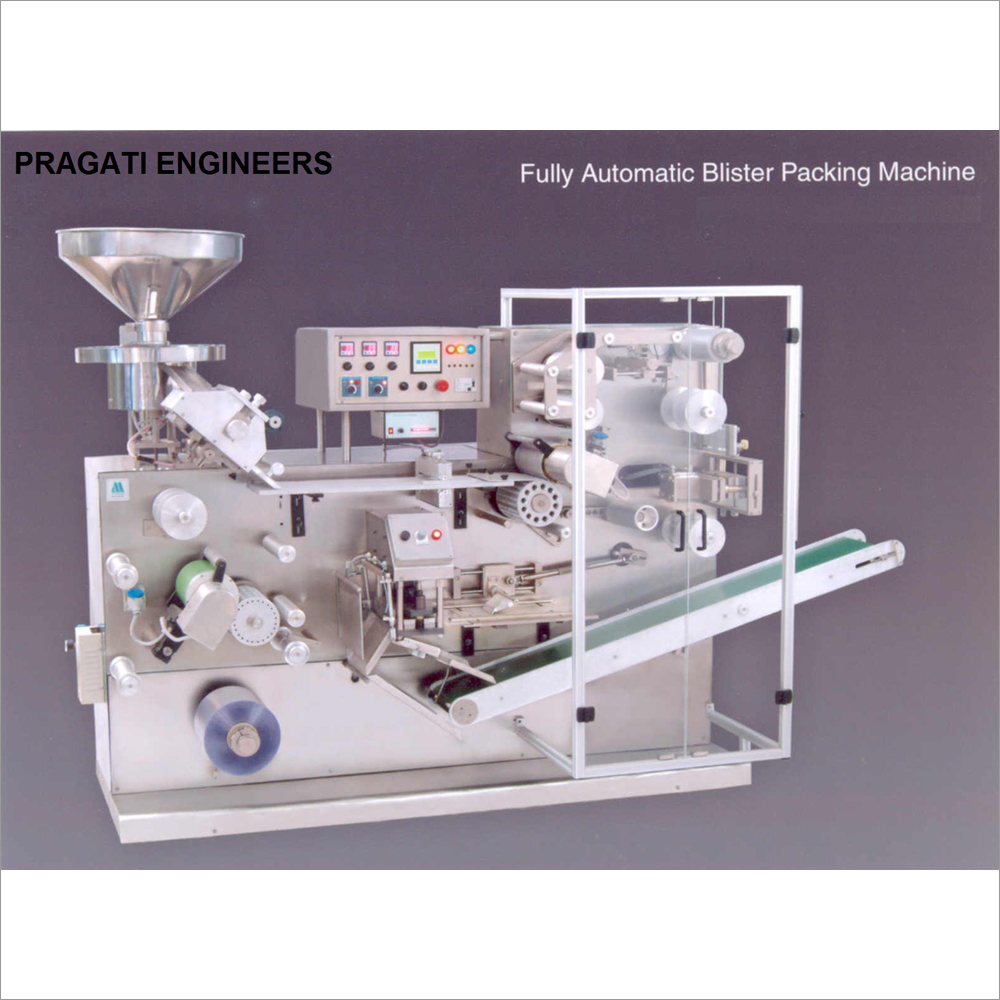

Most Popular Products

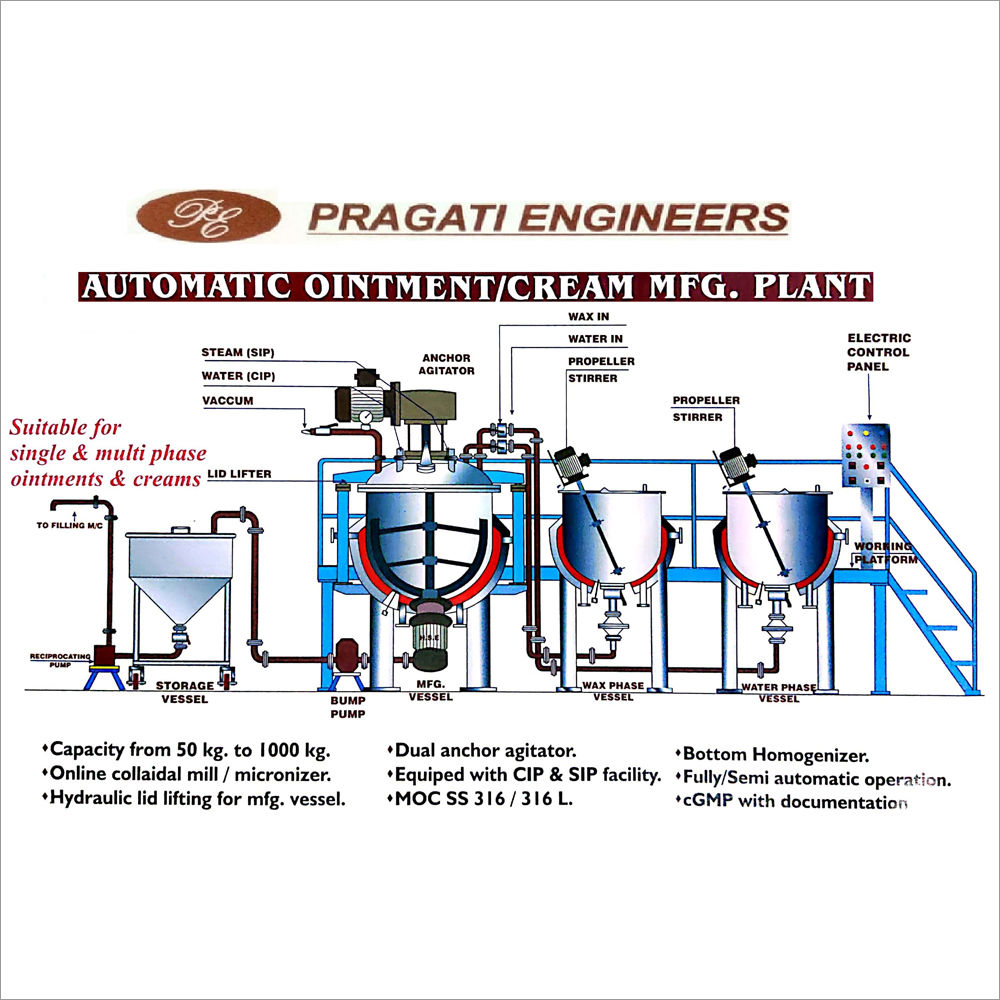

Automatic Ointment Cream Manufacturing Plant

Automatic Ointment Cream Manufacturing Plant Specification

- Lubricating System

- Automatic grease lubrication

- Operating Temperature

- Room Temperature to 120C

- Cooling System

- Integrated water jacket for rapid cooling

- Motor Power

- 3 HP to 15 HP (model/project specific)

- Control System

- PLC controlled with touch screen interface

- Voltage

- 220V/380V/415V (three-phase)

- Connectivity Options

- SCADA/PLC interface, USB data logging

- Frequency

- 50/60 Hz

- Frame Type

- Compact modular skid-mounted

- Power Rating

- 10 HP - 40 HP (model dependent)

- Model No

- AOM-series

- Noise Level

- 75 dB

- Machine Type

- Emulsifying mixer with vacuum system

- Drive

- Direct coupled motor drive

- Features

- Vacuum operation, CIP/SIP compatibility, dust & contamination proof, hydraulic tilting, rapid mixing and emulsification

- Accuracy

- 0.5% on batch quantity

- Production Capacity

- 50-1000 kg per batch

- Product Type

- Automatic Ointment Cream Manufacturing Plant

- Technology

- Fully automatic, cGMP compliant, homogenization

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 10 kW (varies by capacity and model)

- Pressure

- Atmospheric/Nitrogen pressure as required

- Surface Treatment

- Stainless steel 304/316 mirror polish

- Dimension (L*W*H)

- Customized as per requirement

- Weight (kg)

- 1200 kg approx. (depends on capacity)

- Color

- Metallic/Silver

- Usage & Applications

- Manufacturing ointments, creams, cosmetics, gels, and pharmaceutical formulations

- Panel Material

- SS304/316 electrical control panel

- Vacuum Level

- -0.08 MPa (typical)

- Discharge Type

- Hydraulic tilting, bottom valve, or transfer pump

- Sterilization Compatibility

- CIP/SIP compatible design

- Safety Features

- Overload, overheat, and emergency stop protection

- Vacuum Pump

- Oil-sealed rotary vane pump included

- Installation Support

- On-site commissioning and training available

- Operator Interface

- HMI with recipe management and batch traceability

- Optional Accessories

- Load cell for batch weighing, temperature & pressure sensors, online sampling valve

- GMP Compliance

- Designed for pharmaceutical and cosmetic GMP standards

- Validation

- Documentation for DQ, IQ, OQ, PQ available as per pharma norms

- Batch Timers

- Programmable with process alarms

- Heating System

- Electric/Steam heating (jacketed vessel)

- Material Handles

- Viscous, semi-solid and lotion type masses

- Agitator Type

- Anchor with Teflon scrapper and high-shear homogenizer

- Seal Type

- Mechanical/semi-mechanical seals on moving shafts

- Cleaning

- Inbuilt spray balls for automatic cleaning

Automatic Ointment Cream Manufacturing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units, , Per Day

- Delivery Time

- 2 Week

About Automatic Ointment Cream Manufacturing Plant

The Automatic Ointment Cream Manufacturing Plant is made available by us for efficient use in the industry. The Plant is ideal tools for the Pharmaceuticals & Cosmetic industries for the production of Ointment, Cream, Lotions, Gels, Shampoo, and Toothpaste. The plant has a high speed and is very safe and efficient. It is very durable and suitable for manufacturing various types of creams and ointments. The Automatic Ointment Cream Manufacturing Plant is very useful.

High-Efficiency Mixing and Homogenization

This plant utilizes a direct-coupled anchor agitator with Teflon scrapper and integrated high-shear homogenizer, enabling uniform blending and rapid emulsification of viscous ointments, creams, gels, and lotions. Its advanced vacuum operation removes air, reducing product oxidation and ensuring smooth, contaminant-free preparation, suitable for high-quality pharmaceutical and cosmetic outputs.

Robust Safety and GMP Compliance

The manufacturing system is equipped with robust safety features, including overload, overheat, and emergency stop protection, in compliance with pharmaceutical GMP standards. Automated cleaning (CIP/SIP compatibility), batch traceability, and full validation documentation (DQ, IQ, OQ, PQ) streamline regulatory approvals, providing confidence in process reliability and end-product quality.

Advanced Control & Customization

A PLC-controlled, HMI touch screen interface allows easy operation, recipe management, and real-time batch monitoring. Options for SCADA/PLC connectivity and USB data logging enhance traceability, while programmable batch timers, process alarms, and load cells (optional) support accuracy and process consistency as per specific manufacturing requirements.

FAQs of Automatic Ointment Cream Manufacturing Plant:

Q: How does the automatic ointment cream plant ensure consistent product quality?

A: The plant is equipped with a high-shear homogenizer and anchor agitator with a Teflon scrapper, providing thorough mixing and uniform emulsification. The vacuum operation removes air and contaminants, while PLC controls with recipe management and batch traceability ensure repeatable, high-quality results.Q: What types of materials can be processed in this manufacturing plant?

A: The system is designed to handle viscous, semi-solid, and lotion-type masses, making it suitable for a wide array of products such as ointments, creams, gels, cosmetic formulations, and pharmaceuticals that require precise homogenization and contamination control.Q: When should the cleaning cycle be initiated, and how is cleaning performed?

A: Cleaning can be scheduled after each batch or as dictated by standard operating procedures. Inbuilt spray balls and automatic CIP/SIP compatibility enable thorough in-place cleaning with minimal manual intervention, supporting high standards of hygiene and reducing downtime.Q: Where can this plant be installed, and what installation support is provided?

A: The compact, modular skid-mounted design allows installation in pharmaceutical, cosmetic, and related manufacturing facilities. On-site commissioning, validation support, and operator training services are available to ensure seamless integration and successful setup.Q: What is the process flow for manufacturing creams or ointments with this equipment?

A: Raw materials are loaded into the jackted vessel, where electric or steam heating melts and pre-mixes ingredients. The anchor agitator and high-shear homogenizer blend the mixture under vacuum. Once homogenized, the product is discharged via hydraulic tilting, bottom valve, or transfer pump, followed by automatic cleaning.Q: How does the plant benefit manufacturers in terms of productivity and compliance?

A: Fully automated controls, programmable batch timers, and precise recipe management minimize manual effort, reduce batch-to-batch variation, and increase output consistency. GMP-compliant design, thorough documentation, and inbuilt safety features ensure regulatory adherence and operational reliability.Q: What optional accessories enhance the versatility of this ointment manufacturing plant?

A: Options like load cells for batch weighing, integrated temperature and pressure sensors, and an online sampling valve can be added. These features further optimize batch accuracy, process monitoring, and quality assurance, making the plant adaptable to varying production requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ointment Section Machines Category

Container Filling Machine

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Powder Coated

Power Source : Other, Electric

Color : Stainless Steel

Operating Type : Automatic

Planetary Mixer Jacketed

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Stainless Steel Polished

Power Source : Other, Electric

Color : Metallic Silver

Operating Type : Other, SemiAutomatic / Automatic

Automatic Tube Filling & Sealing Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Power Source : Electricity

Color : Silver

Operating Type : Automatic

|

PARAG EXPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese